A decision-support framework can help legislators understand which plastic waste management pathways best balance economic, environmental, and circularity goals. Increasing levels of plastic waste, combined with unsustainable waste management infrastructure, pose profound challenges to environmental sustainability and human welfare.

Contemporary waste management systems remain dominated by landfilling and incineration, both of which impose environmental burdens and prevent the recovery of reuseable materials. Post-industrial waste (PIW) is an underutilized, high-value recycling stream due to its low contamination and well-defined composition, providing opportunities to reduce resource use, environmental impacts, and costs. Yet, determining optimal management strategies is difficult given the range of emerging technologies and the need to weigh multiple, often competing, objectives.

To address this challenge, we propose an optimization-based framework that identifies the most suitable technologies for PIW plastic streams by clarifying the trade-offs between economic performance and environmental outcomes. The framework involves identifying feasible technologies, representing their combinations as a full network of possible pathways, defining economic and environmental objectives, and formulating an optimization model to determine optimal solutions.

Our case study examines a mixed plastic feedstock that reflects the types of materials commonly found in PIW, including polyethylene (PE), polyethylene terephthalate (PET), nylon (N6), and ethylene-vinyl alcohol (EVOH). We evaluate both emerging and established technologies that can process these materials, such as pyrolysis, gasification, and a solvent-based separation method known as the Solvent-Targeted Recovery and Precipitation (STRAP™) process, along with conventional options like incineration, and landfilling. Because STRAP relies on solvents to separate the components, we also apply a solvent screening step to determine which polymers can be targeted and which solvents can be used.

The aim of the analysis is to understand how each possible pathway performs with respect to financial cost, environmental impact, and circularity. To do this, we estimate costs and potential revenues, evaluate greenhouse gas emissions, and assess circularity considering aspects like material recovery, resource consumption and waste generation. Together, these measures capture the economic, environmental, and circularity implications of different pathways to provide a clearer picture of the tradeoffs involved in managing complex plastic waste streams.

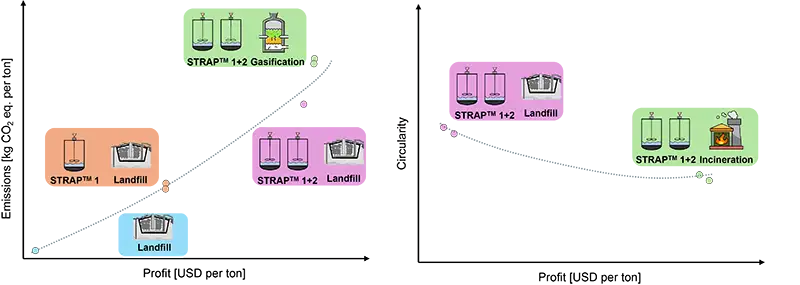

The results indicate that different waste management choices have different strengths and impacts. For the location and PIW stream composition studied, STRAP combined with incineration or gasification produces the highest financial return. Landfilling results in the lowest greenhouse gas emissions, while pairing STRAP with landfilling is the most circular alternative.

The results demonstrate the real trade-offs between the economic and environmental goals. Options that generate more profit often come with higher emissions and lower circularity. By making these tradeoffs visible, the framework helps decision makers compare pathways on equal footing and choose approaches that best align with economic goals, environmental commitments, and long-term resource management needs.

Author Affiliations

UW–Madison Department of Chemical and Biological Engineering:

- Paola Munoz Briones, doctoral student, paola.munozbriones@wisc.edu

- Ugochukwu Ikegwu, doctoral student, Ikegwu@wisc.edu

- Kenneth Martinez, doctoral student, kjmartinez4@wisc.edu

- Charles Granger, doctoral student, cgranger2@wisc.edu

- Reid Van Lehn, Sobota Associate Professor, vanlehn@wisc.edu

- Victor Zavala, Baldovin-DaPra Professor, zavalatejeda@wisc.edu

- Styliani Avraamidou, Duane H. and Dorothy M. Bluemke Assistant Professor, avraamidou@wisc.edu