Wisconsin has an opportunity to lead the nation in next-generation plastics recycling through a breakthrough UW–Madison technology that can recycle plastics previously thought unrecyclable. The plastic packaging industry is a cornerstone of Wisconsin’s economy, ranking eighth nationally in plastics employment and third in flexible plastic packaging with major companies like Amcor, Berry Global, and Glenroy supporting thousands of jobs.

However, this thriving sector also produces hundreds of millions of pounds of plastic waste annually, much of which cannot be recycled with current technologies.

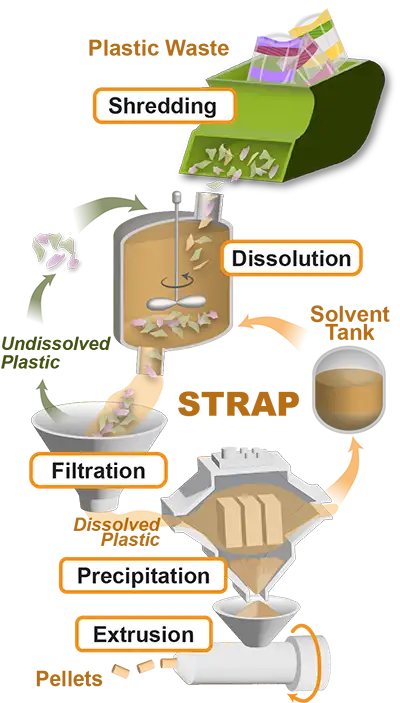

To address this challenge, researchers at UW–Madison’s Center for Chemical Upcycling of Waste Plastics (CUWP) have developed a breakthrough recycling technology called Solvent-Targeted Recovery and Precipitation (STRAP™).

STRAP makes it possible to recycle plastics that were previously unrecyclable, including multilayer packaging, flexible films, and rigid packaging material. It works by selectively dissolving and purifying individual polymers from mixed plastic waste, producing high-quality recycled plastics without degrading their properties.

Traditional recycling systems are limited to clean, rigid containers, even though flexible packaging accounts for 40 percent of all plastic packaging waste as it is especially difficult to recycle. STRAP overcomes this challenge by removing contaminants such as food residue, paper, inks, adhesives, and metal, allowing recovery of valuable materials that would otherwise be landfilled or incinerated.

Investing in advanced plastic recycling technologies like STRAP will strengthen Wisconsin’s economy by creating new manufacturing and engineering jobs, supporting local supply chains, and attracting private investment in recycling infrastructure. Economic analysis shows plastics recycled by STRAP can be cost-competitive with virgin plastics, particularly at scale.

With improvements to waste collection and sorting systems, Wisconsin could become a national leader in advanced recycling, driving economic growth and job creation while reducing reliance on fossil fuels.

STRAP also offers major environmental benefits, reducing greenhouse gas emissions by 60 to 80 percent compared to producing new plastics from petroleum and reduces waste disposal requirements. This directly supports Wisconsin’s goals for sustainability and climate action.

To transition from laboratory development to large-scale industry use, STRAP must be demonstrated at commercial scale. The UW team is partnering with Amcor to test recycled plastics on industrial equipment and is building a 25 kg/hr pilot plant with Michigan Technological University, expected to be operational in early 2026.

Wisconsin is uniquely positioned to lead the nation in next-generation plastics recycling, and we are eager to work with industry, government, and community partners whose collaboration will be essential to scaling this promising technology and building a more sustainable and economically vibrant future for our state.

Author Affiliations

UW–Madison Department of Chemical and Biological Engineering:

- Charles Granger, doctoral student, cgranger2@wisc.edu

- Elizaveta Radkevich, doctoral student, radkevich@wisc.edu

- Lily Callen, doctoral student, lrcallen2@wisc.edu

- Hedam Kim, doctoral student, hkim2257@wisc.edu

- Tushar, doctoral student, tlnu@wisc.edu

- Reid van Lehn, Sobota Associate Professor, vanlehn@wisc.edu

- George W. Huber, Richard L. Antoine Professor, gwhuber@wisc.edu